Working principle of lightweight electric

power-assisted bicycle - rear axle hook sensor

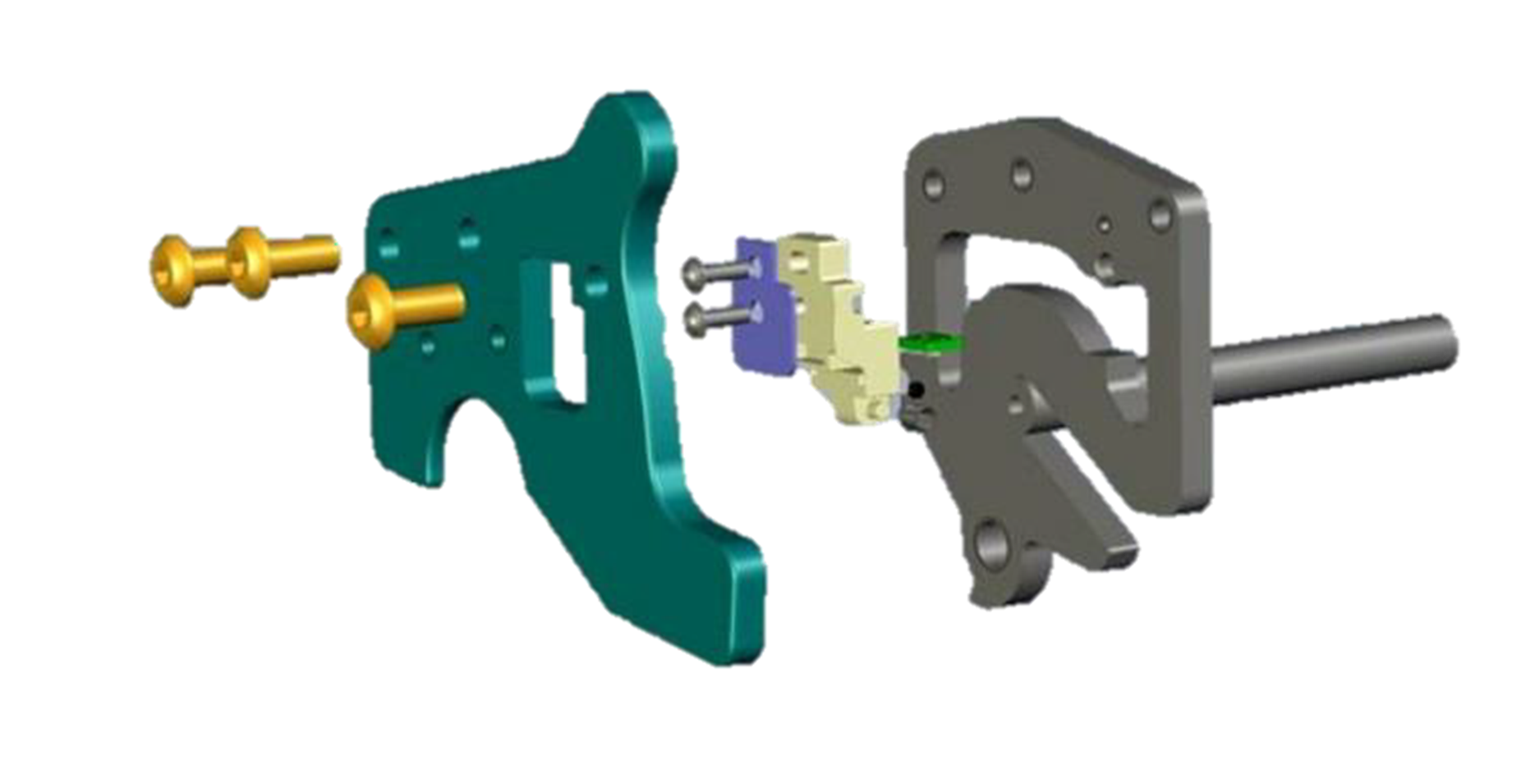

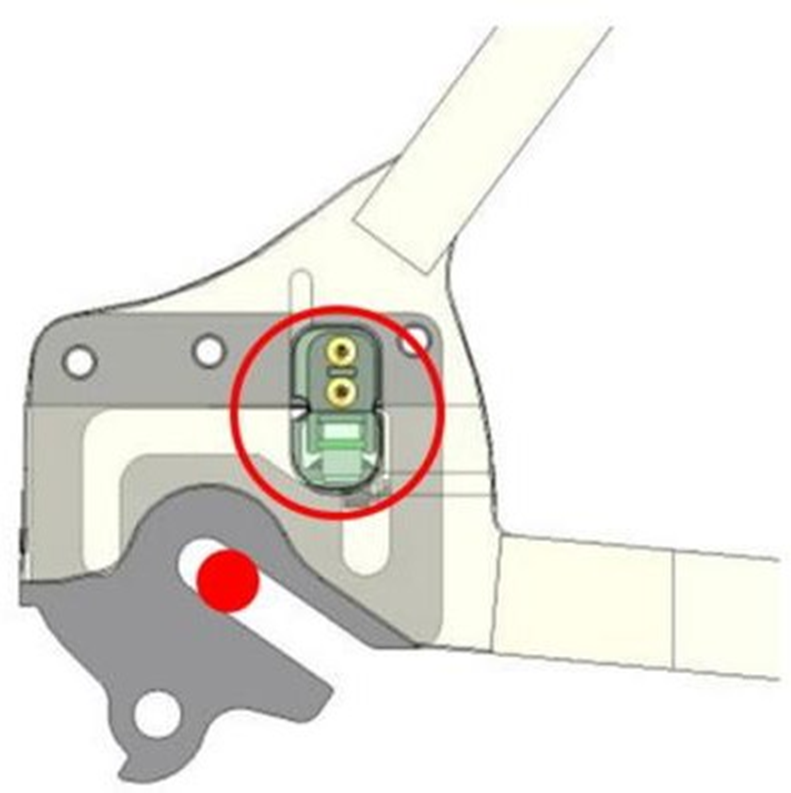

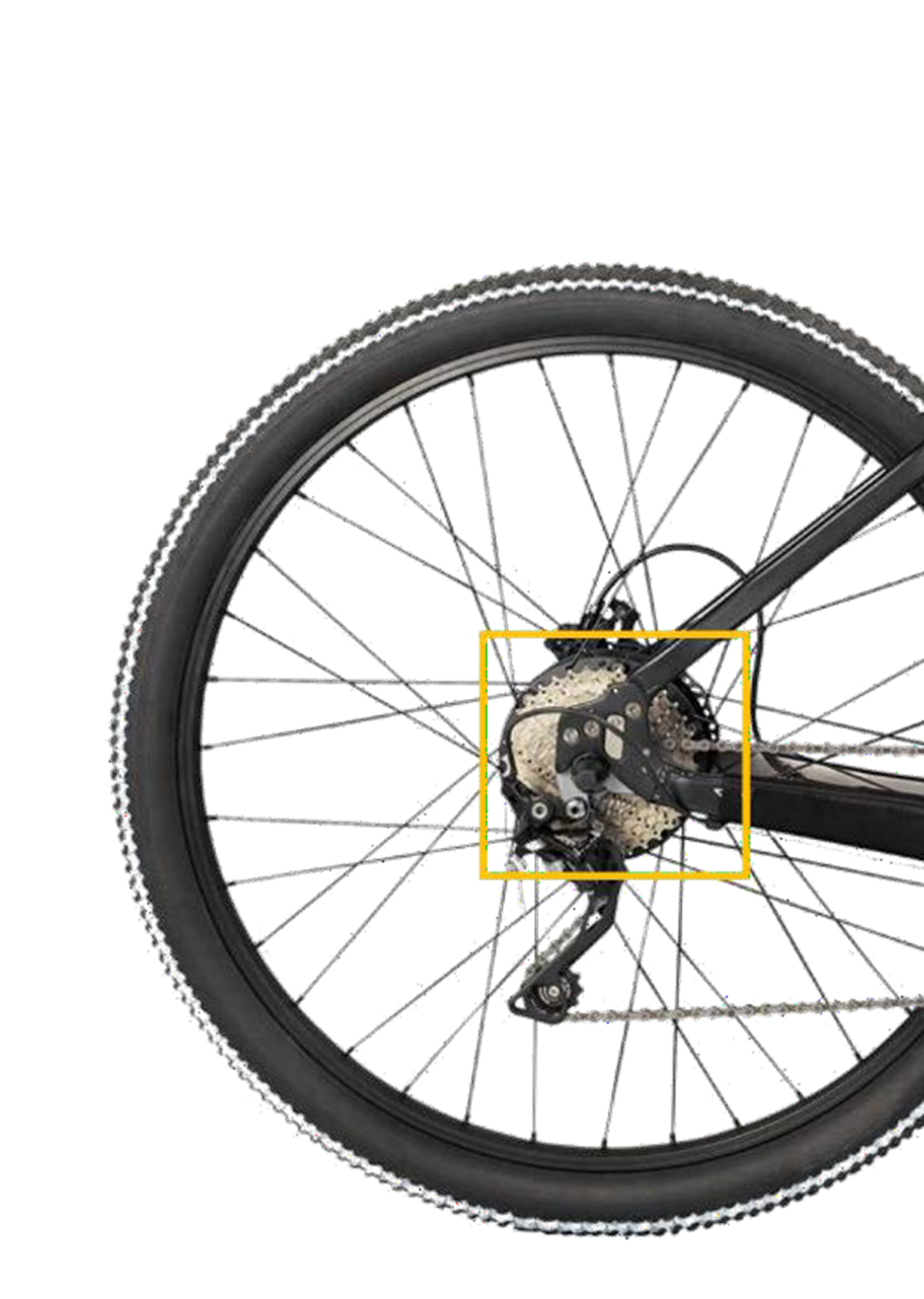

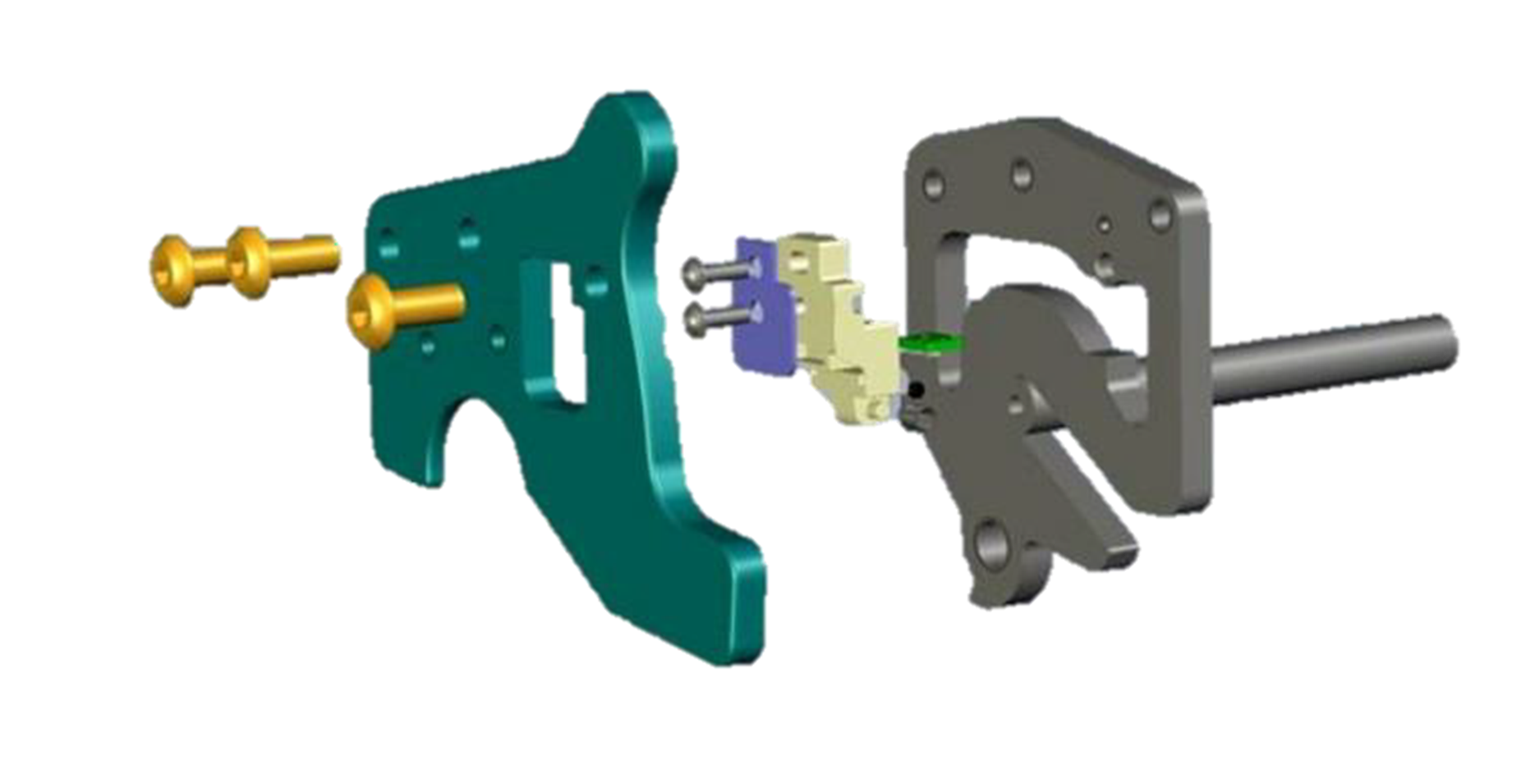

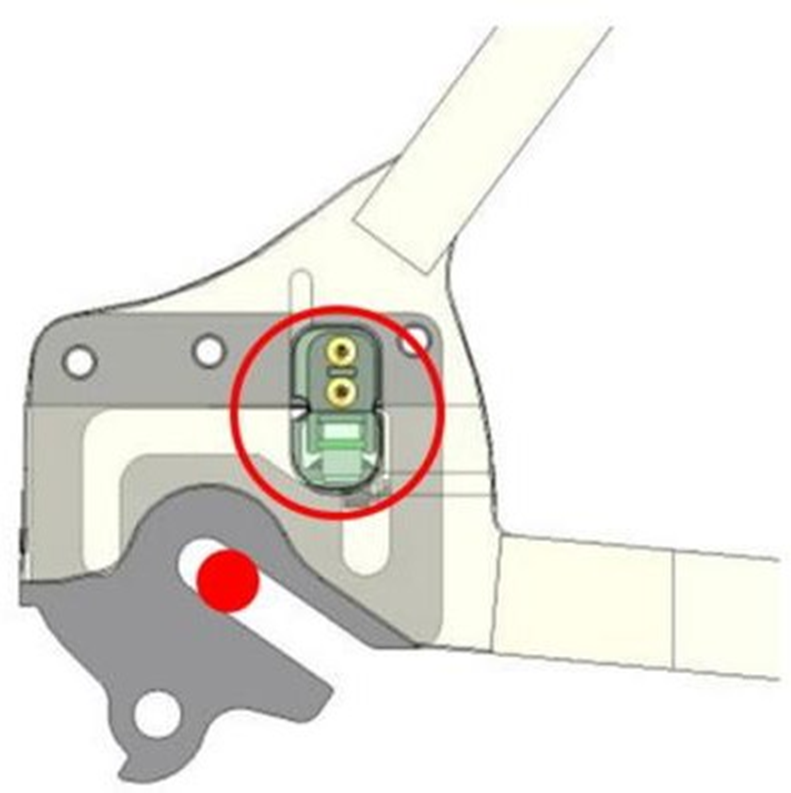

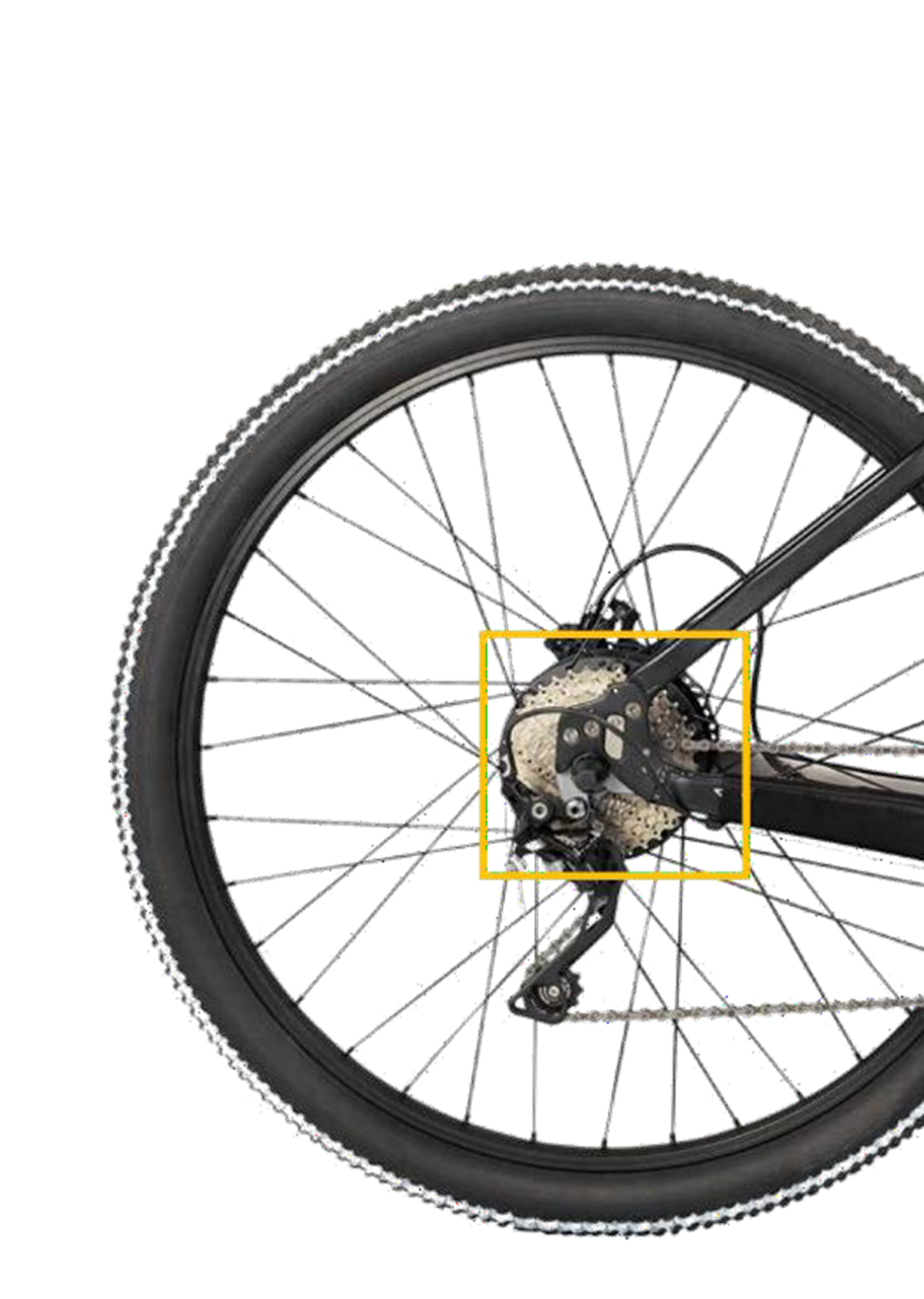

The gray component in the figure is the "rear axle hook sensor",

which is installed at the junction of the rear seat fork and the rear

chainstay, that is, the installation position of the rear axle (the red dot in

the figure is the rear axle). It is equivalent to an additional adapter,

generally made of aluminum alloy. The power of the bicycle forward is

transmitted to the rear axle hook sensor through the rear axle, and then

transmitted to the bicycle frame. When the rear axle hook sensor receives the

force from the rear axle, it will deform, and then squeeze the pressure sensor

in the red circle in the above figure, and then mobilize the battery motor to

provide power for the electric assisted bicycle. The advantages of the rear

axle hook sensor are simple principle, simple structure, and low production

price. If the electric assisted bicycle is always used on a straight road, it

is also good (used in low-end electric assisted bicycles of BH and GIANT, and

Xiaomi electric assisted folding bicycles), but under real road conditions, the

shortcomings of this sensor are also exposed - the measurement torque is not

accurate and delayed, and the riding experience is poor; the production process

of the vehicle is high, and the cost saved by the sensor is transferred to the

frame processing; the aluminum alloy material is easy to deform, the service

life is short, and the user's subsequent maintenance cost is high. Therefore,

the slightly higher-end electric assisted bicycles have abandoned this

type of sensor.

+86 21 59241315

+86 21 59241315  sales@xvyanprecision.com

sales@xvyanprecision.com

No 969, YunHan Road Pudong District Shanghai City China

No 969, YunHan Road Pudong District Shanghai City China